Flannel looks like a simple fabric. Soft, matte, and colorful. Because of this, it's often forgotten how much technology and choice goes into that single roll of fabric. Understanding how flannel is made also reveals why quality, weight, and behavior vary so much between seemingly similar products.

This is the process, step by step.

From cotton to fiber

It all starts with cotton. Flannel for professional use is almost always made from cotton fibers, selected for their length and purity.

Long fibers provide:

– less fluff

– a more even surface

– better sustainability with reuse

After harvesting, the cotton is cleaned and combed. Impurities are removed, and the fibers are aligned. What remains is not "cotton wool," but a controlled raw material.

Spinning: from fiber to yarn

The cotton fibers are spun into yarn. This is a crucial step, as it lays the foundation for strength and density.

Important choices:

– thickness of the yarn

– tension while spinning

– degree of twist

More twist creates strength, less twist creates softness. Flannel sits right in that tension zone. Too loose and it pills, too tight and it loses its absorbent, matte finish.

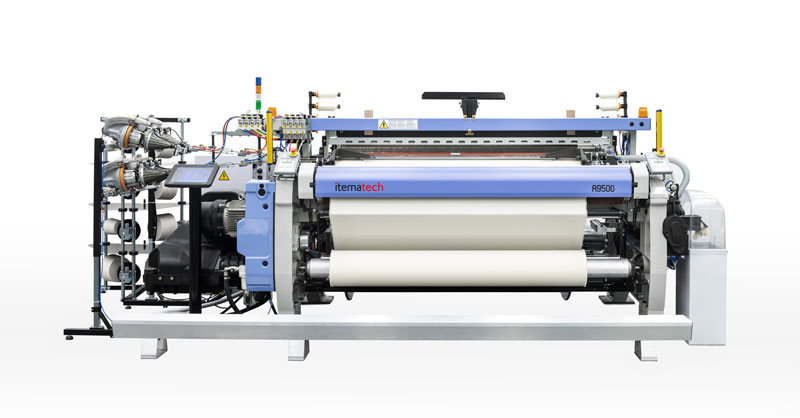

Weaving: structure above all

The spun yarn is woven into cloth, usually in a simple weave, but with a high density.

This is where properties such as:

– light absorption

– tear resistance

– how “open” or “closed” the canvas feels

The weight (for example, 160 or 200 g/m²) is largely determined here. Not by thickness alone, but by the amount of yarn used per square meter.

Rough: the soft character of flannel

After weaving, the cloth is roughened. Rotating brushes lift up small fibers.

This ensures:

– the soft surface

– extra light attenuation

– better acoustic absorption

Too much roughening makes the canvas fragile. Too little roughening makes it hard and shiny. Here, too, balance is key.

Painting: color is chemistry and optics

Flannel is usually dyed as a woven piece: the cloth goes into the dye bath as a whole.

Professional flannel is all about:

– color fastness

– evenness

– predictable behavior under light

Black is notorious. Two black flannels can appear identical under daylight and completely different under LED. That difference arises here, in the combination of pigment, fiber, and degree of roughness.

Fire-resistant: necessary, but not self-evident

For use in events and on stages, flannel must be flame-retardant. This is usually achieved through a post-treatment.

Important to know:

– fire resistant ≠ fireproof

– treatment is washable

– it influences stiffness and durability

Proper treatment slows flame spread. Poor treatment is immediately noticeable: stiff, shiny, and less absorbent.

Drying, checking and cutting

After all treatments, the cloth is dried, checked for color and weight, and cut to length.

Here it is decided:

– roll or bale

– 30 or 60 meters

– packaging form

Minor deviations become visible here. Good factories remove these before packaging.

Packaging: the final technical step

Packaging may seem trivial, but it determines how flannel arrives at its destination.

Professional packaging means:

– tightly rolled up

– protected against moisture

– minimal distortion